Payment Type:L/C,T/T,MoneyGram,cash

Incoterm:FOB,CFR,CIF,EXW

Transportation:Land,Air,Ocean,Express

Port:shanghai

$12.950-2499Others

$12.82500-4999Others

$12.6≥5000Others

Brand: HY

Brand Name: HY

Model Number: HY-852

Material: Steel, Stainless steel,heat resistant stainless

Type: Welding Parts

Plating: Zinc

Weight: according to the drawing

Certification: Iso9001:2015

Dimensions: upon customer's drawings

Application: CGL & CAL

Warranty: 1 Year

Place Of Origin: Jiangsu, China

Packaging: wapped in seaworthy wooden cases or as per customers' request

Productivity: 2000 Ton/Tons per Month

Transportation: Land,Air,Ocean,Express

Place of Origin: China

Supply Ability: 2000 Ton/Tons per Month

Certificate: ISO9001-2015

HS Code: 8514909000

Port: shanghai

Payment Type: L/C,T/T,MoneyGram,cash

Incoterm: FOB,CFR,CIF,EXW

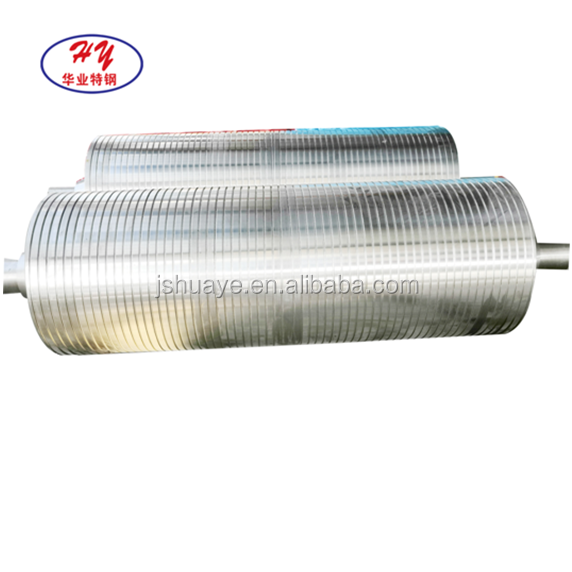

Centrifugal casting Sink Roll for Continuous Annealing line for rolling mill

Centrifugal casting is a process used to manufacture large metal parts. Molten metal is injected into the mold by rotating the mold, and centrifugal force is used to evenly distribute the metal in the mold, resulting in high-quality parts. The centrifugally cast Sink Roll is a special type of centrifugally cast parts, usually used in industrial equipment such as rolling mills.

The manufacturing process of centrifugally cast sinking rollers includes the following steps:

1. Design the mold: Design a suitable centrifugal casting mold according to the size and shape requirements of the Stainless Steel Sink Roll.

2. Prepare the molten metal: Select a suitable metal material and melt it into a liquid state.

3. Mold grouting: Inject molten metal into the rotating mold, and use centrifugal force to evenly fill the mold with the metal.

4. Cooling and solidification: After the metal has fully filled the mold, stop rotating and let the metal cool and solidify.

5. Take out the parts: After the metal is completely solidified, take out the mold to get the sinking roller parts.

The advantages of Centrifugal Casting Stabilizer Roller include high density, high strength, smooth surface, etc. Sink Roller is suitable for manufacturing industrial equipment parts that require high precision and high wear resistance.

| Product name | Sink rollers |

| Specification | OD.50mm to OD.1600mm |

| Properties | good heat, corrosion, wear resistant properties, |

| Sink rolls Materials | High Nickel and high Chrome heat resistant alloys, Cobalt base alloys, like. HU,HT,HK,HP,HW,24/24NbTiZr,50Cr/50Ni(2.4813),1.4865,1.4849,1.4848, 1.4410,1.4059,1.4841, 1.4845,1.4852, 2.4879 or as per customer's requirements |

| Process | Centrifugal casting for barrel/tube, forging for journal/shaft, static /investment or sand casting for cone/ trunnions, welding and machining and grinding. |

| Application | Working at high temperature environment on average: 800-1200°C, which are used in the steel mills, like CAL(continuous annealing line),CGL(continuous galvanizing line). |

| QA&QC | We have in-house facility for each inspection: Composition by Spectrometer; Size test, Mechanical test, NDT, UT, RT, PT, MT, ET |

| Standard | ANSI,ASTM,ASME,DIN,GB etc. |

| Certificates | ISO9001:2015 |

| Advantages | More than 30 years of professional experience and continuous R&D efforts enable us to offer better custom design and engineering advice. Experienced workers for foundry,machining and welding guarantee excellent quality and prompt delivery. Focused sales and customer-service team are working with 100% passion to offer you a five-star purchase experience |

Specifications:

Furnace Roll:used in metallurgical industry furnaces

Centrifugal cast.High nickle and high chromium alloy.

Consumption reduce

The followings are photos for factory and products:

1. Q: How To give inquiry ?

A: Step 1, please tell us what weight ,dimension, material do you need please;

Step 2, Better help to provide the drawing with above-mentioned details please;

Step 3, when we have enough details, we may quote accordingly;

2 . Q: When will make delivery ?

A: Delivery Time

-Sample Order: 15 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 40 days after receipt of the deposit.

3. After-sales Service

1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

4. Payment

T/T, Western Union, Moneygram ,cash.

5. Transportation

Transported by DHL, UPS, EMS, Fedex,Air freight. sea freight.

6. Do you support drop shipping?

Yes,your drop shipping is aviable.